Components

Tank Construction System

Save time and effort with the formwork system exclusively available from us for a wide variety of concrete structures – for the highest demands

Our tank construction system was celebrated as a true innovation in 2011 and has been an integral part of our plants ever since.

Formprotect®

The modular tank construction system.

Innovative System

brings Advantages

Additional coating, insulation and impregnation, is not necessary as all elements are already integrated. The system is absolutely gas- and water-tight as well as acidresistant. The exterior wall does not need to be insulated, painted or cladded with wood.

Formprotect® is also available as a revision system, e. g. for the renovation of existing tanks. During refurbishment, profile rails are placed at specific intervals over the entire surface of the concrete wall. Then the formwork structure is built up from special brackets and formwork panels. The cavity between the concrete wall and the formwork is filled with lightweight concrete, resulting in a strong and stable bond.

- In contrary to conventional tank construction, the easy-to-clean formwork remains as the inner and outer cladding

- The exterior wall does not need to be insulated, painted or cladded

- Chemical-resistant PVC elements: absolutely gasand water-tight as well as acid-resistant

- Concrete and weather protection already integrated, no concrete curing required

- Easy to clean

- Tanks are equipped with leakage detection as standard

- Easy installation of insulation: simply slides between concrete and external formwork

- Weather-independent assembly of the formwork

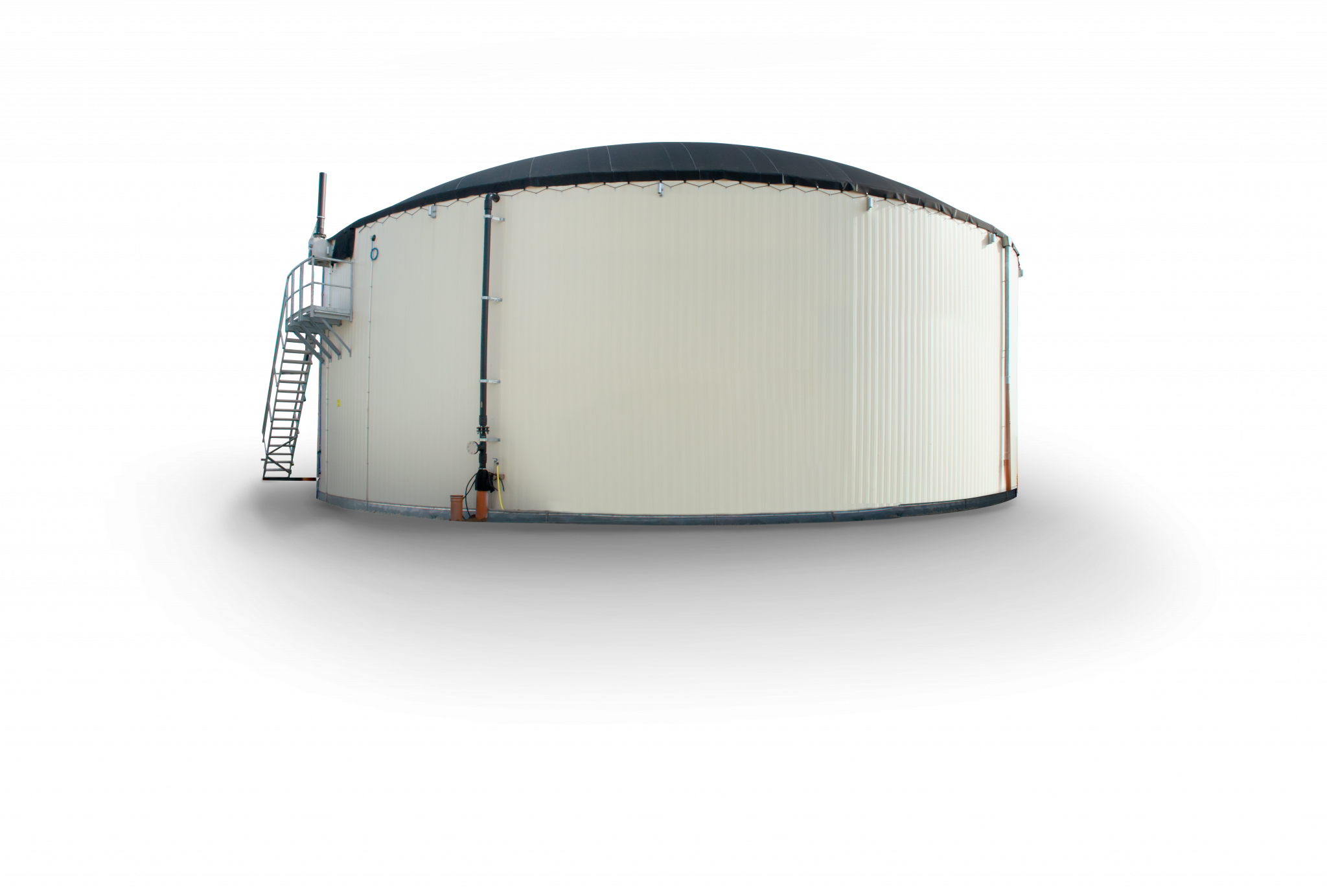

- The appearance impresses with its modern design and colour (RAL 1013 pearl white)

- The appearance impresses with its modern design and colour (RAL 1013 pearl white)

- Complete and ready – from day one; without any subsequent work

stable PVC elements

Patented System

Formprotect® is a new, patented system of lost formwork made of plastic which is constructed from PVC elements in a plug-in system. After concreting, the plastic formwork becomes an integral part of the structure. From a functional point of view, the resulting reinforced concrete composite structure consists of three container shells in one wall: the plastic shell on the inside, the reinforced concrete wall with and without insulation as the core, and the plastic shell on the outside.

- thermoplastic resin

- high chemical resistance

- practically insoluble in water

- insensitive to UV radiation

- insensitive to ozone exposure

- service temperature -50°C to +60°C

- low thermal conductivity

- very resistant to aging